Home : 32mm : Tools : Boring :

Foolproof mating provides accurately aligned dowel joints regardless of material thickness and side fence/stop location. The only requirement is that the drill bits are centered between the table and rear fence (Z=Y). The key difference between this image and the Automatic mating one (use next/prev to switch back and forth) is that foolproof end-boring is done with the inside-face-up (panel A inside up VS down). This allows the Z constant (bit to table distance) to be used for end-boring and provides a common reference point - all panels are bored with their front (or back) edges against the side fence (or back fence stops).

Foolproof mating provides accurately aligned dowel joints regardless of material thickness and side fence/stop location. The only requirement is that the drill bits are centered between the table and rear fence (Z=Y). The key difference between this image and the Automatic mating one (use next/prev to switch back and forth) is that foolproof end-boring is done with the inside-face-up (panel A inside up VS down). This allows the Z constant (bit to table distance) to be used for end-boring and provides a common reference point - all panels are bored with their front (or back) edges against the side fence (or back fence stops).

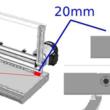

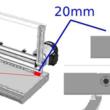

When setting the rear fence, using gauge blocks (G) a bit thicker than the maximum expected panel (P) thickness will allow leaving the fence in place while testing/setting the drill head height. Blocks close to 20mm tall should allow leaving the fence in place for all 3/4 +/- construction boring, e.g. plywood and melamine. Note: Any adjustment of the drill head height is 1:2, e.g. moving it up/back .125mm moves the A panel holes down .125, the B panel holes up .125 and the A panel outside face up .25mm.

When setting the rear fence, using gauge blocks (G) a bit thicker than the maximum expected panel (P) thickness will allow leaving the fence in place while testing/setting the drill head height. Blocks close to 20mm tall should allow leaving the fence in place for all 3/4 +/- construction boring, e.g. plywood and melamine. Note: Any adjustment of the drill head height is 1:2, e.g. moving it up/back .125mm moves the A panel holes down .125, the B panel holes up .125 and the A panel outside face up .25mm.

Foolproof Mating

Foolproof mating provides accurately aligned dowel joints regardless of material thickness and side fence/stop location. The only requirement is that the drill bits are centered between the table and rear fence (Z=Y). The key difference between this image and the Automatic mating one (use next/prev to switch back and forth) is that foolproof end-boring is done with the inside-face-up (panel A inside up VS down). This allows the Z constant (bit to table distance) to be used for end-boring and provides a common reference point - all panels are bored with their front (or back) edges against the side fence (or back fence stops).

Foolproof mating provides accurately aligned dowel joints regardless of material thickness and side fence/stop location. The only requirement is that the drill bits are centered between the table and rear fence (Z=Y). The key difference between this image and the Automatic mating one (use next/prev to switch back and forth) is that foolproof end-boring is done with the inside-face-up (panel A inside up VS down). This allows the Z constant (bit to table distance) to be used for end-boring and provides a common reference point - all panels are bored with their front (or back) edges against the side fence (or back fence stops). When setting the rear fence, using gauge blocks (G) a bit thicker than the maximum expected panel (P) thickness will allow leaving the fence in place while testing/setting the drill head height. Blocks close to 20mm tall should allow leaving the fence in place for all 3/4 +/- construction boring, e.g. plywood and melamine. Note: Any adjustment of the drill head height is 1:2, e.g. moving it up/back .125mm moves the A panel holes down .125, the B panel holes up .125 and the A panel outside face up .25mm.

When setting the rear fence, using gauge blocks (G) a bit thicker than the maximum expected panel (P) thickness will allow leaving the fence in place while testing/setting the drill head height. Blocks close to 20mm tall should allow leaving the fence in place for all 3/4 +/- construction boring, e.g. plywood and melamine. Note: Any adjustment of the drill head height is 1:2, e.g. moving it up/back .125mm moves the A panel holes down .125, the B panel holes up .125 and the A panel outside face up .25mm.