Home : 32mm :

Drawer front registration is very similar to door registration. Like door hinges and mounting plates, drawer front adjusters and mounting screws/holes can be some multiple of 32mm apart, an equal distance from the top/bottom/edges of the (sub)face, and can be adjusted up/down and side to side.

Drawer front registration is very similar to door registration. Like door hinges and mounting plates, drawer front adjusters and mounting screws/holes can be some multiple of 32mm apart, an equal distance from the top/bottom/edges of the (sub)face, and can be adjusted up/down and side to side.

Accurate drawer face registration can be accomplished with adjustable metal drawer slide mounting brackets, adjustable drawer front mounts (20mm press fit, kolbe korner, oversized hole/screw head, etc.), or adjustable drawer slides (no subface or mount adjustment required).

Consistent drawer face registration requires that the drawer slides be located some multiple of 32mm apart and that the drawer faces are some multiple of 32mm tall, less the desired gap between faces. Drawer box sides also need to be sized in 32mm increments if you need/want to use the top of the drawer face/box as a reference point (e.g. Plus 32).

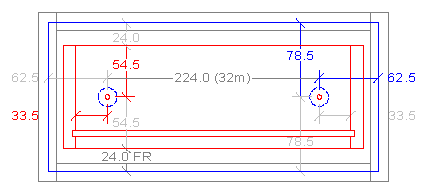

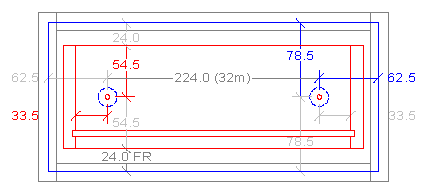

The example (center indexed half overlay) uses 20mm press fit adjusters that default to center, but allow the face to be moved 2mm in any direction (side pressure bends/breaks the centering pins). Making cabinets in 32mm increment widths allows all adjuster holes to be drilled a multiple of 32mm apart and the same distance from the edges of all faces/sub-faces (e.g. 62.5/33.5). All drawers need a common drawer face reveal (FR, e.g. 24) to allow drilling the holes an equal distance from the top and/or bottom of the drawer (e.g. 78.5/54.5).

[ comment | link | top ]

Half-overlay and flush-inset drawers work quite well with true center registration. All drawers have the same top and bottom drawer box face reveal. The one potential issue is that undermount (37 BC ... and Tandembox, 33 BC) drawer layouts work much better with shifted system holes and bottom mount (typ. < 22 BC) layouts work much better when face edges fall on system holes. Note that center indexing bottom mount boxes only works with applied bottom drawer boxes. Side mount slides work either way.

Half-overlay and flush-inset drawers work quite well with true center registration. All drawers have the same top and bottom drawer box face reveal. The one potential issue is that undermount (37 BC ... and Tandembox, 33 BC) drawer layouts work much better with shifted system holes and bottom mount (typ. < 22 BC) layouts work much better when face edges fall on system holes. Note that center indexing bottom mount boxes only works with applied bottom drawer boxes. Side mount slides work either way.

The only difference between the half-overlay and railed inset flush layouts are that the system rows are moved back the thickness of the faces and the drawer faces are 22mm shorter (and narrower, -11 all edges).

The only difference between the half-overlay and railed inset flush layouts are that the system rows are moved back the thickness of the faces and the drawer faces are 22mm shorter (and narrower, -11 all edges).

All system registered half-overlay/railed inset cabinets have slide bottom clearances of 32mm - 1/2 panel thickness (e.g. 32 - 9.5 = 22.5 BC). For shifted registration its 48mm (32+16) - 1/2 panel thickness (e.g. 48 - 9.5 = 38.5 BC).

[ page | comments (4) - Thursday, 20-Aug-2020 | top ]

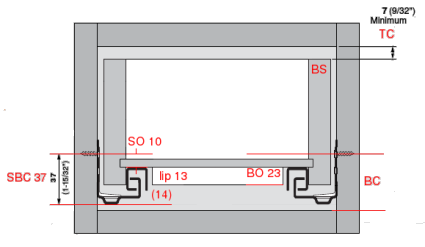

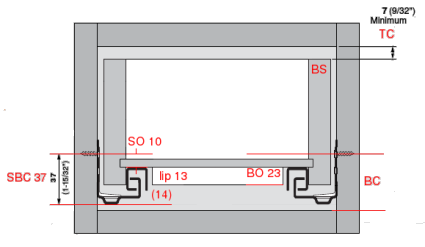

I've used so many acronyms in my drawings that I'm starting to confuse myself. Hopefully the following will help me to standardize them and help you to decipher my drawings. The image is a modified specification drawing for Blum 554H undermount slides. There is also an image showing how specs change when using the bottom mounting holes. Not all dimensions were on the original drawing and the drawings are not to scale.

I've used so many acronyms in my drawings that I'm starting to confuse myself. Hopefully the following will help me to standardize them and help you to decipher my drawings. The image is a modified specification drawing for Blum 554H undermount slides. There is also an image showing how specs change when using the bottom mounting holes. Not all dimensions were on the original drawing and the drawings are not to scale.

Slide Bottom Clearance (BC/SBC) - the distance from the system hole that a slide will mount to, to the top of a horizontal cabinet member. Minimum required BC is the distance from a slide system mounting hole, to the bottom of the slide (lowest point). Used for determining slide to cabinet box bottom, and/or rail/stretcher, clearance. Will the slide work with the layout, will it be reasonably close to horizontal cabinet members. While slide specifications are usually fairly similar, some manufacturers slides won't work with some layouts. One example is Salice under-mounts which require a minimum BC of 42.5/30.5 (top/bottom mounting holes) VS the more standard 37/25 (e.g. Blum)... Note: At least one drawing uses SBO (slide bottom offset) instead of BC (bottom clearance).

Top Clearance (TC) - how much space is needed to install/remove the drawer box. While most slides specify at least a bit of top clearance, this is most important when designing bottom mount drawer layouts - because 3/4 extension bottom mount slides need a relatively large amount of TC.

Bottom mount specifications for top clearance typically assume the drawer box depth is roughly the same as drawer slide length and that the drawer will be pulled straight out. Slide specifications less ~3.5mm will work but require tipping the drawer downward so that the back of the box can clear the carcase when the drawer box wheels go over the carcase wheels. Reducing box top clearance more requires making the drawer boxes shallower than the slides or using full extension slides, i.e. have it so that the back of the drawer box comes past the front edge of the counter-top before the box is removed.

Slide Offset (SO) - the distance from the slide system mounting hole, to the ledge that the drawer box side or bottom sits on. Applies to all bottom and under mount slides. This is a primary variable when designing a drawer layout, or in determining whether or not a manufacturers slide will work with a given layout.

Box Offset (BO) - the distance from the slide system mounting hole, to the bottom of the drawer box (lowest point, typically the sides). Applies to all slides. With under-mounts, this is slide offset (SO) + lip (how much the drawer sides overhang the bottom of the box). With bottom mounts, box offset (BO) is the same as slide offset (SO). Since side mounts have no slide offset (SO), this is the number that matters when designing side mount drawer layouts.

Some drawings only show BO to allow for slight variations in specifications, e.g. '9.5 SO / 13 lip' and '10 SO / 12.5 lip' both have a 22.5 BO. There's also no harm in reducing the '(10 SO /) 13 lip' to 12.5. Note: Inset drawer bottom thickness doesn't matter, only the location of the bottom side of the slot/dado.

Face Offset (FO) - the distance from the slide system mounting hole, to the bottom of the drawer face. Used for calculating face reveal/registration (below).

Overlay and Full Inset Faces

System: 32 (x n) - 1/2 face gap (typ. 30.5)

Shifted: its 32 (x n) + 16 - 1/2 gap (typ. 46.5)

Railed Inset Faces

System: 32 (x n) - (1/2 PT + gap)

Shifted: its 32 (x n) + 16 - (1/2 PT + gap)

Face Registration/Reveal (FR/B2FR) - the distance between the drawer box top/bottom and drawer face top/bottom. To be able to consistently register drawer boxes to faces, the top and/or bottom box to face reveal (B2FR, TFR or BFR) needs to be the same for every drawer in every drawer stack. While it is possible to center register faces (CFR) without having consistent top or bottom face reveals, true center registered faces have equal top and bottom reveals. Reveals for registration can be calculated as follows:

Bottom FR = face offset - box offset

Top FR = face height - box height - bottom FR

Box Side (BS) - the height of the box sides. Typically presented as some multiple of 32mm (plus a constant). While box side height is often the same as box height, box bottoms can run long with the front and back of the box sitting on the top of the box bottom.

[ page | comments (4) - Saturday, 13-Mar-2021 | top ]

Drawers

Drawer layout is dependent on panel design. Panel top and bottom reveals, slide offset, minimum slide clearances and face indexing all affect layout.

Drawer faces are always a multiple of 32mm tall, less gap/reveal. Drawer faces can be indexed with their top and bottom edges (before reveal is subtracted) centered on ("System"), or between ("Shifted"), system holes.

Drawer faces are always a multiple of 32mm tall, less gap/reveal. Drawer faces can be indexed with their top and bottom edges (before reveal is subtracted) centered on ("System"), or between ("Shifted"), system holes.

Face Registration

Drawer front registration is very similar to door registration. Like door hinges and mounting plates, drawer front adjusters and mounting screws/holes can be some multiple of 32mm apart, an equal distance from the top/bottom/edges of the (sub)face, and can be adjusted up/down and side to side.

Drawer front registration is very similar to door registration. Like door hinges and mounting plates, drawer front adjusters and mounting screws/holes can be some multiple of 32mm apart, an equal distance from the top/bottom/edges of the (sub)face, and can be adjusted up/down and side to side. Accurate drawer face registration can be accomplished with adjustable metal drawer slide mounting brackets, adjustable drawer front mounts (20mm press fit, kolbe korner, oversized hole/screw head, etc.), or adjustable drawer slides (no subface or mount adjustment required).

Consistent drawer face registration requires that the drawer slides be located some multiple of 32mm apart and that the drawer faces are some multiple of 32mm tall, less the desired gap between faces. Drawer box sides also need to be sized in 32mm increments if you need/want to use the top of the drawer face/box as a reference point (e.g. Plus 32).

The example (center indexed half overlay) uses 20mm press fit adjusters that default to center, but allow the face to be moved 2mm in any direction (side pressure bends/breaks the centering pins). Making cabinets in 32mm increment widths allows all adjuster holes to be drilled a multiple of 32mm apart and the same distance from the edges of all faces/sub-faces (e.g. 62.5/33.5). All drawers need a common drawer face reveal (FR, e.g. 24) to allow drilling the holes an equal distance from the top and/or bottom of the drawer (e.g. 78.5/54.5).

[ comment | link | top ]

Indexing Wood Drawer Boxes

Balanced drawer boxes, like balanced panels, keep things simple. The following is a simplified version of the old How Wood Drawers Utilize System Holes article. Note: While the basic principles apply to all drawers, this is a fairly half-overlay/inset-flush centric article... more

[ page | comments (4) - Friday, 17-Aug-2012 | top ]

[ page | comments (4) - Friday, 17-Aug-2012 | top ]

Half Overlay Center Indexed

Half-overlay and flush-inset drawers work quite well with true center registration. All drawers have the same top and bottom drawer box face reveal. The one potential issue is that undermount (37 BC ... and Tandembox, 33 BC) drawer layouts work much better with shifted system holes and bottom mount (typ. < 22 BC) layouts work much better when face edges fall on system holes. Note that center indexing bottom mount boxes only works with applied bottom drawer boxes. Side mount slides work either way.

Half-overlay and flush-inset drawers work quite well with true center registration. All drawers have the same top and bottom drawer box face reveal. The one potential issue is that undermount (37 BC ... and Tandembox, 33 BC) drawer layouts work much better with shifted system holes and bottom mount (typ. < 22 BC) layouts work much better when face edges fall on system holes. Note that center indexing bottom mount boxes only works with applied bottom drawer boxes. Side mount slides work either way. The only difference between the half-overlay and railed inset flush layouts are that the system rows are moved back the thickness of the faces and the drawer faces are 22mm shorter (and narrower, -11 all edges).

The only difference between the half-overlay and railed inset flush layouts are that the system rows are moved back the thickness of the faces and the drawer faces are 22mm shorter (and narrower, -11 all edges).All system registered half-overlay/railed inset cabinets have slide bottom clearances of 32mm - 1/2 panel thickness (e.g. 32 - 9.5 = 22.5 BC). For shifted registration its 48mm (32+16) - 1/2 panel thickness (e.g. 48 - 9.5 = 38.5 BC).

[ page | comments (4) - Thursday, 20-Aug-2020 | top ]

Bottom Clearance

Cabinet bottom clearance is the distance from the system hole that a slide will mount to, to the top of a horizontal cabinet member. Drawer slide bottom clearance is the distance from a slide system mounting hole, to the bottom of the slide (lowest point). The required drawer slide bottom clearance cannot exceed the available cabinet bottom clearance.

Working with 19mm material and 3mm gaps, all drawer faces overlay all drawer rails/stretchers 8mm and the bottom clearance is 22.5 for system registered faces and 38.5 when using shifted face registration. With all shared panel cabinets, the bottom of the cabinet has a reveal of at least 11 (i.e. <= 8mm overlay) and the rail BC numbers work well - 22.5 for bottom mount/Metabox/Zargon (typ. 16-19 BC) and 38.5 for Blum style undermounts (typ. 37 BC) - for all drawers. The problem with full-overlay is that the bottom drawer face has significantly less reveal/more overlay on the cabinet bottom (VS at the rails). What compounds the issue is that the available BC is not close to standard slide BC's. This is why there is a full page covering full-overlay bottom clearance

The table uses a 19mm panel thickness (PT) and a 3mm gap (g). Bottom Clearance (BC) = start hole (+/-32) - PT.

[ comment | link | top ]

Working with 19mm material and 3mm gaps, all drawer faces overlay all drawer rails/stretchers 8mm and the bottom clearance is 22.5 for system registered faces and 38.5 when using shifted face registration. With all shared panel cabinets, the bottom of the cabinet has a reveal of at least 11 (i.e. <= 8mm overlay) and the rail BC numbers work well - 22.5 for bottom mount/Metabox/Zargon (typ. 16-19 BC) and 38.5 for Blum style undermounts (typ. 37 BC) - for all drawers. The problem with full-overlay is that the bottom drawer face has significantly less reveal/more overlay on the cabinet bottom (VS at the rails). What compounds the issue is that the available BC is not close to standard slide BC's. This is why there is a full page covering full-overlay bottom clearance

The table uses a 19mm panel thickness (PT) and a 3mm gap (g). Bottom Clearance (BC) = start hole (+/-32) - PT.

| reveal | overlay | sys start | sys BC | shift start | shift BC | type |

| r | PT - r | 32 - 1/2 g + r | start - PT | 48 - 1/2 g + r | start - PT | |

| 22 | -3 | 52.5 | 33.5 | 68.5 | 49.5 | full inset |

| 11 (22) | 8 (-3) | 41.5 | 22.5 | 57.5 | 38.5 | ALL rails, half-overlay/System32, (railed-inset) |

| 9.5 | 9.5 | 40 | 21 | 56 | 37 | custom |

| 4.5 | 14.5 | 35 | 16 | 51 | 32 | KISS |

| 3 | 16 | 33.5 | 14.5 | 49.5 | 30.5 | custom |

| 1.5 | 17.5 | 32 | 13 | 48 | 29 | modular, Proulx |

| 0 | 19 | 30.5 | 11.5 | 46.5 | 27.5 | modular/True32, Process32 |

[ comment | link | top ]

Full Overlay Bottom Clearance

With half-overlay and inset cabinets, all horizontal carcase components (top, bottom and stretchers/rails) center on, or between, system holes and all drawer openings are the same size (when drawer rails are used). Bottom clearance (BC), the distance from the drawer slide mounting holes to any horizontal component, is the same for all openings.

The only way to get a full overlay on the bottom of the cabinet is to move the bottom of the cabinet up (any other option breaks the system, e,g, unbalanced hinge cup boring). Moving the cabinet bottom up reduces the size of the bottom drawer opening and the distance from the drawer slide mounting hole to the bottom of the cabinet. Because the drawer slides are mounted some multiple of 32mm apart, the reduced bottom drawer clearance results in wasted space under the rest of the drawers. The following covers ways to minimize wasted space, but the bottom line is that you either use the 32mm system and waste some space, or trade some of the consistency that the system provides for more usable space... more

[ page | top ]

The only way to get a full overlay on the bottom of the cabinet is to move the bottom of the cabinet up (any other option breaks the system, e,g, unbalanced hinge cup boring). Moving the cabinet bottom up reduces the size of the bottom drawer opening and the distance from the drawer slide mounting hole to the bottom of the cabinet. Because the drawer slides are mounted some multiple of 32mm apart, the reduced bottom drawer clearance results in wasted space under the rest of the drawers. The following covers ways to minimize wasted space, but the bottom line is that you either use the 32mm system and waste some space, or trade some of the consistency that the system provides for more usable space... more

[ page | top ]

Full Overlay Undermount

6-24-18: Updated drawings with drawer boxes sized to provide consistent top drawer face reveals (24) and clearance (6.5). Drawer box increments match face increments (5,9,10). System/shifted registration examples are aligned/comparable. Examples are balanced 3g/1.5r 19mm panels. For 3/0r, shift the system rows down 1.5 or decrease top face reveals by 1.5 (and use hinge plate adjustment to move doors down 1.5). Blue is good, red is potentially bad.

Shifted registration layouts (48mm starts). The first is straight 32mm system and requires that the slides be mounted using the lower (by 12mm) row of mounting holes (not all undermounts have them). The second layout uses 32mm smaller bottom drawer boxes and standard/top mounting holes to improve the usable space for all but the bottom drawers. The third layout has 12mm smaller bottom drawer boxes mounted 12mm higher. It requires slides with two rows of mounting holes and a second set of incremental drawer boxes (32m - 73 bottom, 32m - 51 everywhere else). The forth layout requires drilling special mounting holes for the bottom drawer to allow center (only) registration using 32mm smaller bottom drawer boxes.

Shifted registration layouts (48mm starts). The first is straight 32mm system and requires that the slides be mounted using the lower (by 12mm) row of mounting holes (not all undermounts have them). The second layout uses 32mm smaller bottom drawer boxes and standard/top mounting holes to improve the usable space for all but the bottom drawers. The third layout has 12mm smaller bottom drawer boxes mounted 12mm higher. It requires slides with two rows of mounting holes and a second set of incremental drawer boxes (32m - 73 bottom, 32m - 51 everywhere else). The forth layout requires drilling special mounting holes for the bottom drawer to allow center (only) registration using 32mm smaller bottom drawer boxes.

System registration layouts (32mm starts). The straight 32mm system layout works with all undermount slides and can use top or bottom (32mm increment boxes not required) registration. The minus 32 bottom box layout requires a lower row of mounting holes and off system rails (if used), the shifted registration version requires neither. The minus 20 bottom box layout is the system registration version of the minus 12 bottom box with the addition of off system rails. The only difference between the two center registration layouts is that this one requires additional mounting holes for all but the bottom drawer (VS bottom only).

System registration layouts (32mm starts). The straight 32mm system layout works with all undermount slides and can use top or bottom (32mm increment boxes not required) registration. The minus 32 bottom box layout requires a lower row of mounting holes and off system rails (if used), the shifted registration version requires neither. The minus 20 bottom box layout is the system registration version of the minus 12 bottom box with the addition of off system rails. The only difference between the two center registration layouts is that this one requires additional mounting holes for all but the bottom drawer (VS bottom only).

The 32mm system layouts have consistent top and bottom drawer face reveals, the minus 32/12/20 layouts have consistent top reveals. The 32mm system, minus 32 and center registration layouts have 32mm increment drawer boxes, minus 12/20 bottom drawer boxes are 12/20mm smaller (not the same increments as the rest of the boxes). The top row mounted 32mm system and minus 32mm methods work with all drawer slide types, the 12/20 method only works with 2 row slides. The tradeoffs are consistency VS usable space. The center only (true HO/RI center indexing has equal t/b reveals) indexing options are usefull when drilling centered adjuster and pull holes at the same time. Note that all but the 32mm system layouts have one less drawer box size. The same is true for any layout with a bottom drawer box that is one increment larger than the one above, e.g. 5,6,6,7.

[ comment | link | top ]

Shifted registration layouts (48mm starts). The first is straight 32mm system and requires that the slides be mounted using the lower (by 12mm) row of mounting holes (not all undermounts have them). The second layout uses 32mm smaller bottom drawer boxes and standard/top mounting holes to improve the usable space for all but the bottom drawers. The third layout has 12mm smaller bottom drawer boxes mounted 12mm higher. It requires slides with two rows of mounting holes and a second set of incremental drawer boxes (32m - 73 bottom, 32m - 51 everywhere else). The forth layout requires drilling special mounting holes for the bottom drawer to allow center (only) registration using 32mm smaller bottom drawer boxes.

Shifted registration layouts (48mm starts). The first is straight 32mm system and requires that the slides be mounted using the lower (by 12mm) row of mounting holes (not all undermounts have them). The second layout uses 32mm smaller bottom drawer boxes and standard/top mounting holes to improve the usable space for all but the bottom drawers. The third layout has 12mm smaller bottom drawer boxes mounted 12mm higher. It requires slides with two rows of mounting holes and a second set of incremental drawer boxes (32m - 73 bottom, 32m - 51 everywhere else). The forth layout requires drilling special mounting holes for the bottom drawer to allow center (only) registration using 32mm smaller bottom drawer boxes. System registration layouts (32mm starts). The straight 32mm system layout works with all undermount slides and can use top or bottom (32mm increment boxes not required) registration. The minus 32 bottom box layout requires a lower row of mounting holes and off system rails (if used), the shifted registration version requires neither. The minus 20 bottom box layout is the system registration version of the minus 12 bottom box with the addition of off system rails. The only difference between the two center registration layouts is that this one requires additional mounting holes for all but the bottom drawer (VS bottom only).

System registration layouts (32mm starts). The straight 32mm system layout works with all undermount slides and can use top or bottom (32mm increment boxes not required) registration. The minus 32 bottom box layout requires a lower row of mounting holes and off system rails (if used), the shifted registration version requires neither. The minus 20 bottom box layout is the system registration version of the minus 12 bottom box with the addition of off system rails. The only difference between the two center registration layouts is that this one requires additional mounting holes for all but the bottom drawer (VS bottom only).The 32mm system layouts have consistent top and bottom drawer face reveals, the minus 32/12/20 layouts have consistent top reveals. The 32mm system, minus 32 and center registration layouts have 32mm increment drawer boxes, minus 12/20 bottom drawer boxes are 12/20mm smaller (not the same increments as the rest of the boxes). The top row mounted 32mm system and minus 32mm methods work with all drawer slide types, the 12/20 method only works with 2 row slides. The tradeoffs are consistency VS usable space. The center only (true HO/RI center indexing has equal t/b reveals) indexing options are usefull when drilling centered adjuster and pull holes at the same time. Note that all but the 32mm system layouts have one less drawer box size. The same is true for any layout with a bottom drawer box that is one increment larger than the one above, e.g. 5,6,6,7.

[ comment | link | top ]

Drawer Terms and Acronyms

I've used so many acronyms in my drawings that I'm starting to confuse myself. Hopefully the following will help me to standardize them and help you to decipher my drawings. The image is a modified specification drawing for Blum 554H undermount slides. There is also an image showing how specs change when using the bottom mounting holes. Not all dimensions were on the original drawing and the drawings are not to scale.

I've used so many acronyms in my drawings that I'm starting to confuse myself. Hopefully the following will help me to standardize them and help you to decipher my drawings. The image is a modified specification drawing for Blum 554H undermount slides. There is also an image showing how specs change when using the bottom mounting holes. Not all dimensions were on the original drawing and the drawings are not to scale.Slide Bottom Clearance (BC/SBC) - the distance from the system hole that a slide will mount to, to the top of a horizontal cabinet member. Minimum required BC is the distance from a slide system mounting hole, to the bottom of the slide (lowest point). Used for determining slide to cabinet box bottom, and/or rail/stretcher, clearance. Will the slide work with the layout, will it be reasonably close to horizontal cabinet members. While slide specifications are usually fairly similar, some manufacturers slides won't work with some layouts. One example is Salice under-mounts which require a minimum BC of 42.5/30.5 (top/bottom mounting holes) VS the more standard 37/25 (e.g. Blum)... Note: At least one drawing uses SBO (slide bottom offset) instead of BC (bottom clearance).

Top Clearance (TC) - how much space is needed to install/remove the drawer box. While most slides specify at least a bit of top clearance, this is most important when designing bottom mount drawer layouts - because 3/4 extension bottom mount slides need a relatively large amount of TC.

Bottom mount specifications for top clearance typically assume the drawer box depth is roughly the same as drawer slide length and that the drawer will be pulled straight out. Slide specifications less ~3.5mm will work but require tipping the drawer downward so that the back of the box can clear the carcase when the drawer box wheels go over the carcase wheels. Reducing box top clearance more requires making the drawer boxes shallower than the slides or using full extension slides, i.e. have it so that the back of the drawer box comes past the front edge of the counter-top before the box is removed.

Slide Offset (SO) - the distance from the slide system mounting hole, to the ledge that the drawer box side or bottom sits on. Applies to all bottom and under mount slides. This is a primary variable when designing a drawer layout, or in determining whether or not a manufacturers slide will work with a given layout.

Box Offset (BO) - the distance from the slide system mounting hole, to the bottom of the drawer box (lowest point, typically the sides). Applies to all slides. With under-mounts, this is slide offset (SO) + lip (how much the drawer sides overhang the bottom of the box). With bottom mounts, box offset (BO) is the same as slide offset (SO). Since side mounts have no slide offset (SO), this is the number that matters when designing side mount drawer layouts.

Some drawings only show BO to allow for slight variations in specifications, e.g. '9.5 SO / 13 lip' and '10 SO / 12.5 lip' both have a 22.5 BO. There's also no harm in reducing the '(10 SO /) 13 lip' to 12.5. Note: Inset drawer bottom thickness doesn't matter, only the location of the bottom side of the slot/dado.

Face Offset (FO) - the distance from the slide system mounting hole, to the bottom of the drawer face. Used for calculating face reveal/registration (below).

Overlay and Full Inset Faces

System: 32 (x n) - 1/2 face gap (typ. 30.5)

Shifted: its 32 (x n) + 16 - 1/2 gap (typ. 46.5)

Railed Inset Faces

System: 32 (x n) - (1/2 PT + gap)

Shifted: its 32 (x n) + 16 - (1/2 PT + gap)

Face Registration/Reveal (FR/B2FR) - the distance between the drawer box top/bottom and drawer face top/bottom. To be able to consistently register drawer boxes to faces, the top and/or bottom box to face reveal (B2FR, TFR or BFR) needs to be the same for every drawer in every drawer stack. While it is possible to center register faces (CFR) without having consistent top or bottom face reveals, true center registered faces have equal top and bottom reveals. Reveals for registration can be calculated as follows:

Bottom FR = face offset - box offset

Top FR = face height - box height - bottom FR

Box Side (BS) - the height of the box sides. Typically presented as some multiple of 32mm (plus a constant). While box side height is often the same as box height, box bottoms can run long with the front and back of the box sitting on the top of the box bottom.

[ page | comments (4) - Saturday, 13-Mar-2021 | top ]